Throughout history, the mechanized systems for concrete production were through elements similar to circular containers or pots where, by mixing, the materials that make up the concrete were allowed to knead each other. This system or form of production was adapted over time, giving birth to the now known mixers that are currently used by companies that sell concrete. They have been mounted for many decades on trucks that have served as carriers of the product in the mixing process from the loading point, to the final destination where it is poured directly or pumped into the elements.

Likewise, the growth of cities and the densification of the population have made even more challenging every day to transport concrete, fighting to preserve the necessary qualities, detonating a growing additive industry that has had to intervene by formulating different types of them for different climatic conditions, timing, distances and specifications, increasing costs and making the mixing and production designs more complex.

However, a more advanced generation has come to change the rules of the game, simplifying the process and avoiding the problems that time and distance generate in the concrete, even opening an important opportunity area to the use of additives in a smarter way for the improvement of the final product. This is just one of the many advantages and opportunities that a new generation system offers, with a wide range of them that become great business opportunities, such as:

Low initial investment cost to venture into the sale of concrete or concrete production.

Low initial investment cost to venture into the sale of concrete or concrete production. Expansion of niche market by location, because it can be transported long distances or being able to move and produce on site anywhere, expanding the spectrum of work and monopolizing any opportunity of emerging markets where the supply of concrete is difficult.

Expansion of niche market by location, because it can be transported long distances or being able to move and produce on site anywhere, expanding the spectrum of work and monopolizing any opportunity of emerging markets where the supply of concrete is difficult. Market use in the sector of low consumption quantities, being able to serve any customer even with minimal needs.

Market use in the sector of low consumption quantities, being able to serve any customer even with minimal needs. Taking advantage of technology and its characteristics for production in projects of high consumption volumes, significantly increasing the amount of production on site per unit, reducing marginal costs and increasing profitability.

Taking advantage of technology and its characteristics for production in projects of high consumption volumes, significantly increasing the amount of production on site per unit, reducing marginal costs and increasing profitability. Perfect for the production of special concrete of any specification of resistance, tempering or even optimal for temperature control.

Perfect for the production of special concrete of any specification of resistance, tempering or even optimal for temperature control. Opportunity to reduce cement consumption and direct costs.

Opportunity to reduce cement consumption and direct costs. Reduction in costs of installed infrastructure, permits and plant personnel.

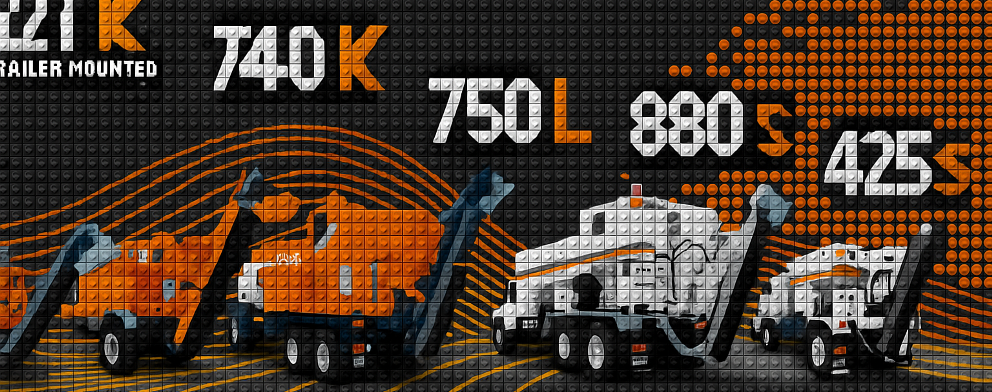

Reduction in costs of installed infrastructure, permits and plant personnel.These advantages and many more have made owning Mobile Continuous Concrete Mixing equipment the best alternative, even in long-term business models. A sample of that is that some countries in the world have a significant growing market share, and so many companies and entrepreneurs have seen their great benefits day by day.

← Back to Blog